Innovative solutions for hydraulic drive and control technology

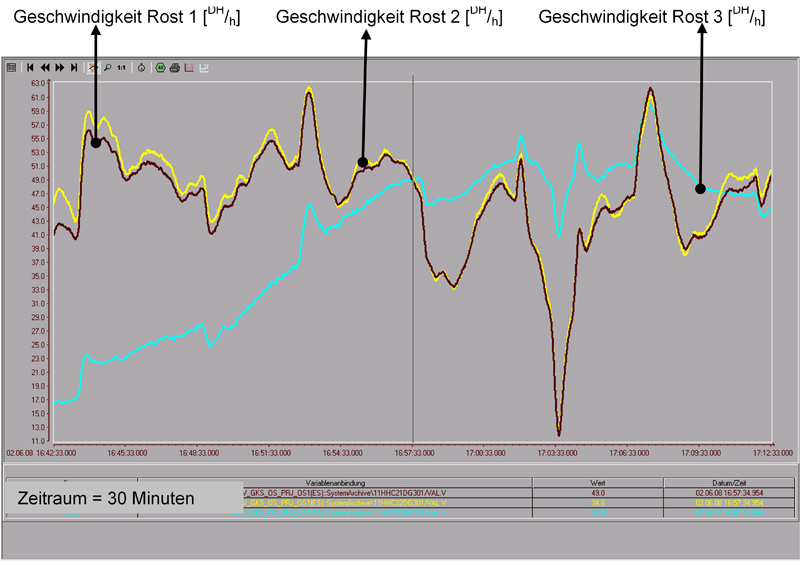

As a result, our experience with the control and regulation of grate furnaces is also of benefit to us in the construction of control systems for the associated hydraulic systems. For example, it is essential for a combustion control system (FLR) that all hydraulic drives, such as grate and fuel feed, can be fully controlled and regulated. This is the only way in which suitable movement sequences for each incineration process can be established.

SAR also consciously and consistently emphasises the keywords "open and transparent" in relation to its hydraulic control systems. For the following reasons, we prefer the implementation of a location or position and synchronisation control, for example, as a pure software solution.

This means that you can save on additional electronic equipment (e.g. modules for a position control or a synchronisation control). This is also frequently designed as proprietary systems, which establish dependencies to the supplier and represent additional expenses for the spares inventory.

The software solution favoured by us offers the following advantages:

- In contrast to electronic modules, software is designed transparently and verifiably, which greatly facilitates troubleshooting.

- Software is not subject to any age-related wear or a drift.

- Software can be changed at any time, and can be adapted to changed operating conditions (e.g. valve replacement).

- The cost of a software solution is identical compared to a solution using electronic modules.

- Electronics modules often have limited availability on the part of the manufacturer and are subject to a product life cycle, which often does not correlate with the life span of large-scale plants. The software solution can always be migrated by any supplier. This means that there is never a dependent relationship.

Product and service range in the hydraulics sector

For new plants, as well as in part for the modernisation of existing plants:

- Project planning of complete hydraulic plants

- Hydraulic cylinders, hydraulic power units

- Hydraulic piping, installation

- Planning, construction and installation of hydraulic cabinets

- Proportional valve technology with associated electronic amplifier modules

- Regulation and control technology for hydraulic systems (location controls, synchronisation controls, etc.)

- Innovative and conventional operating systems for quick fault diagnosis and efficient service or maintenance